Improve your processes. Avoid surprises and extra expenses.

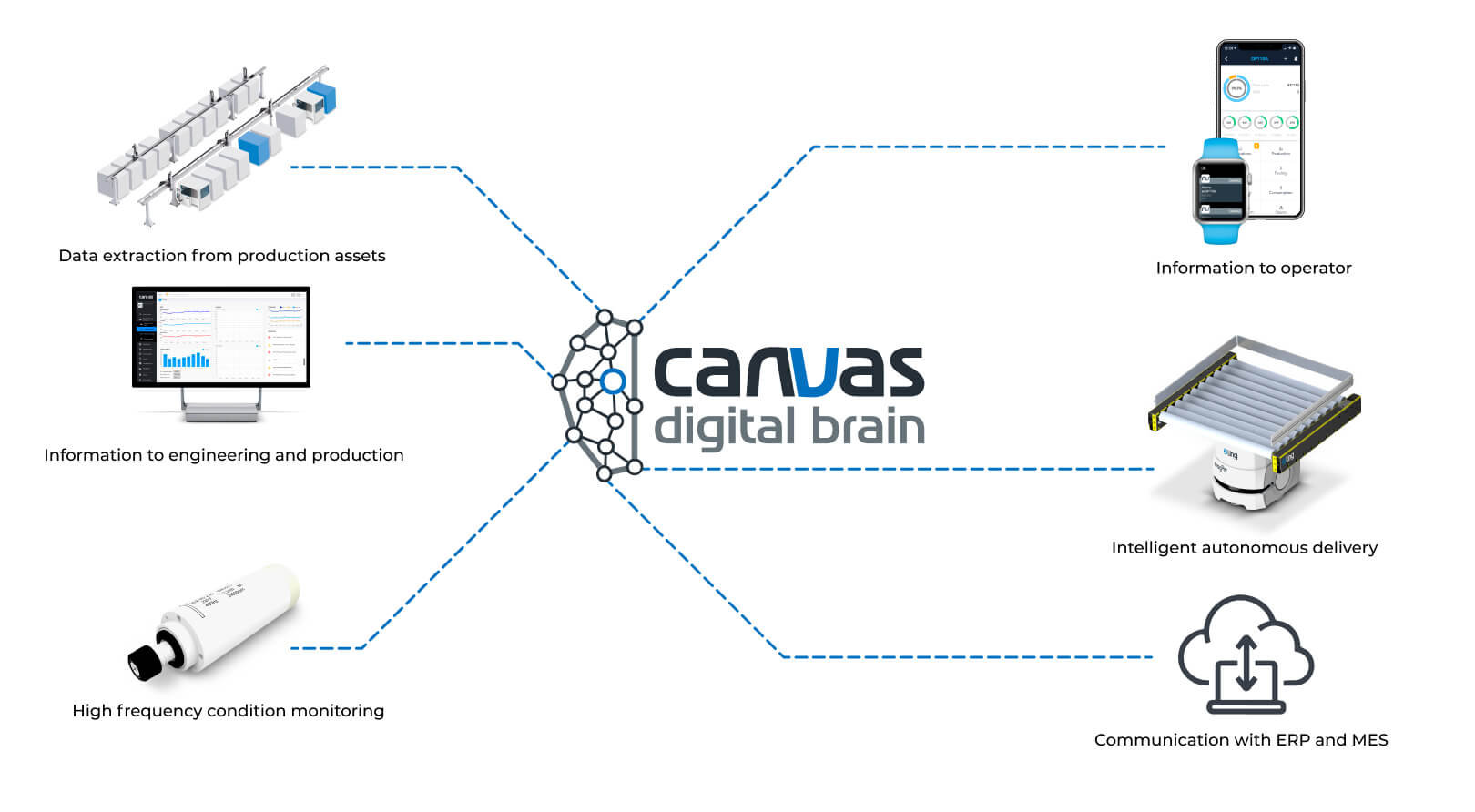

CANVAS DIGITAL BRAIN

The smart middleware to streamline your in-plant operations in real time.

OUR SYSTEM

CANVAS DIGITAL BRAIN is composed of several flexible modules, contributing to the process of digital transformation in manufacturing plants. These modules can be adapted to each plant’s needs, tackling the detected inefficiencies.

CANVAS DIGITAL BRAIN MODULES

Data Extractor

Through different communication protocols (STEP7, OPC-UA, MQTT, etc.) we are able to connect to PLC and CNC systems to extract the necessary variables that are relevant in the manufacturing process.

Data Viewer

CANVAS Data Viewer allows viewing critical data in an intuitive display. It is a user-friendly dashboard adapted to the data extracted and processed from your manufacturing plant assets.

Flow Manager

Our IA Algorithms process all the relevant information from the manufacturing assets and optimise the tasks to be dispatched in order to ensure smooth in-plant operations. This decision making affects material preparation, task planner, dynamic material delivery among others.

High Frequency Processor

High Frequency Processor connects with the NC unit of the machine and extracts data with a frequency of down to 4 ms. It also processes the information to monitor critical variables of the manufacturing system for a condition based maintenance

Fleet Manager

This module translates the decisions made in the Flow Manager to the motion control of the autonomous vehicles. It includes the factory layout and manages the sequence of tasks to be performed by different families of vehicles.

Communication Node: ERP, MES, etc.

CANVAS DIGITAL BRAIN also reads or writes information with other software layers of the plant such as an ERP or MES System depending on where the information must be stored.