Improve your processes. Avoid surprises and extra expenses.

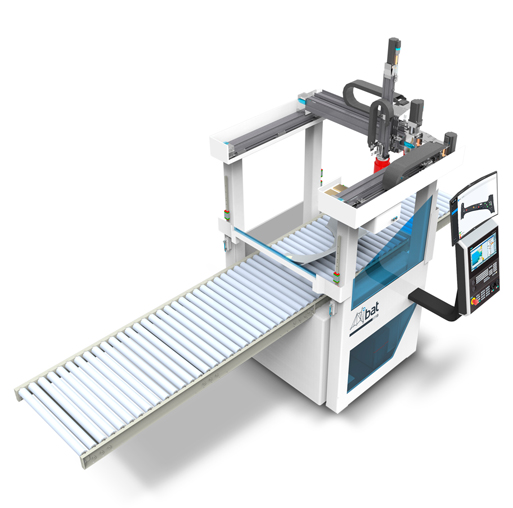

BAT SM

The automatic machine to inspect 100% of your sheet metal part production

Mechanical properties inspection of sheet metal parts in high production environments.

BAT SM OFFERS THE FOLLOWING ADVANTAGES:

Stamping inspection

Surface hardness, yield stress, tensile strength, carburized / diffusion layer, phase change.

Productivity

Machine adapted to the required cycle time, down to 3 seconds/part.

Flexibility

Zero changeover for a broad part spectrum.

User friendliness

Clear display of inspection results for intuitive interpretation.

Advanced traceability

of part quality and process parameters.

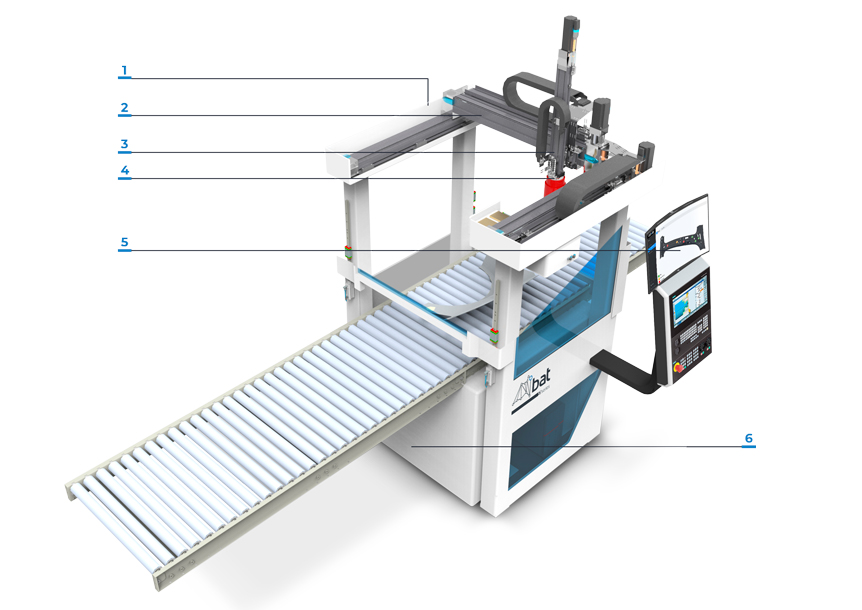

- 1

Automatic inspection

Automatic inspection integrated in line cycle time.

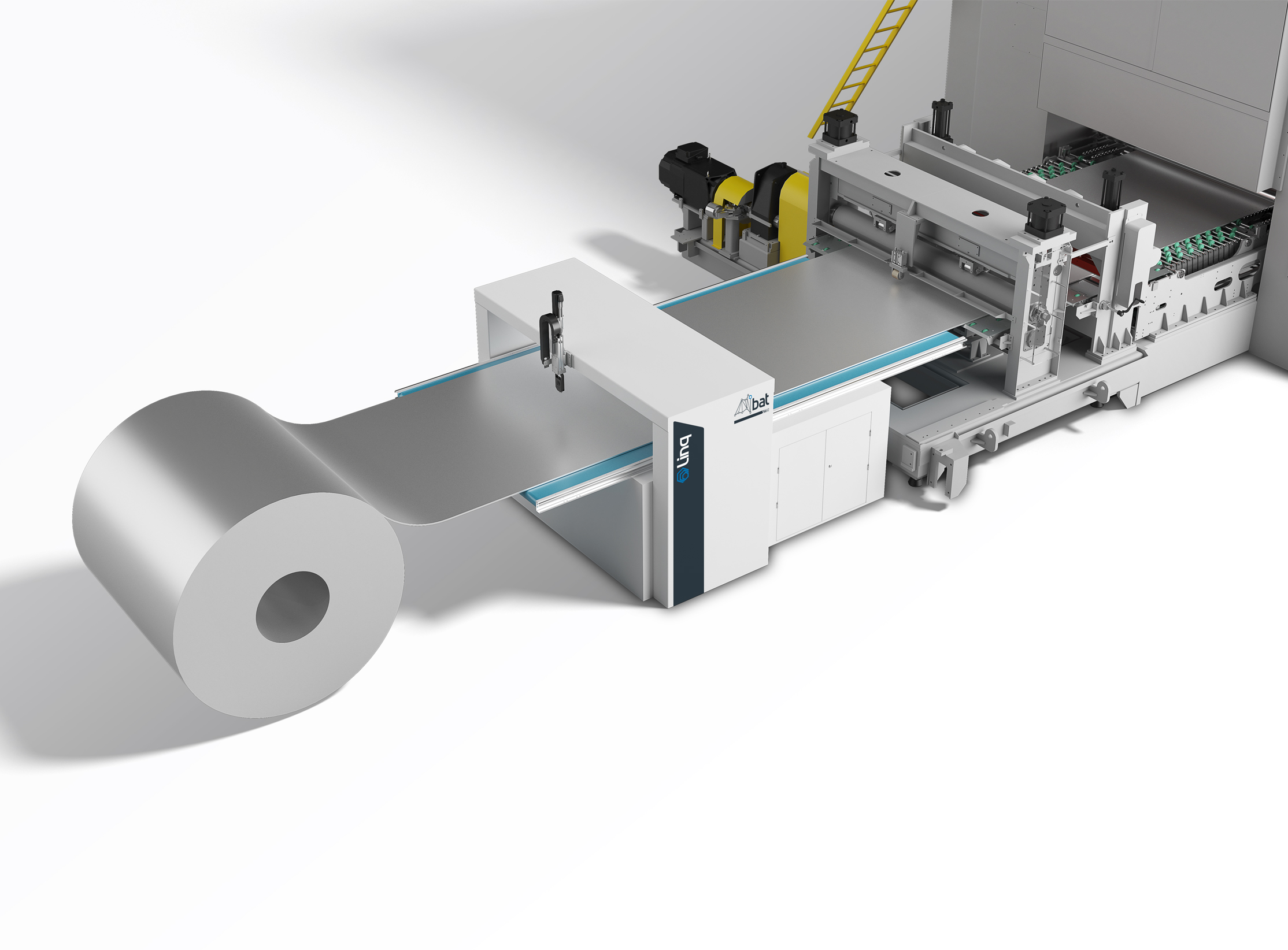

- 2

Gantry configuration

Sensor head can be mounted in an existing gantry or as part of a complete system supplied by LINQ.

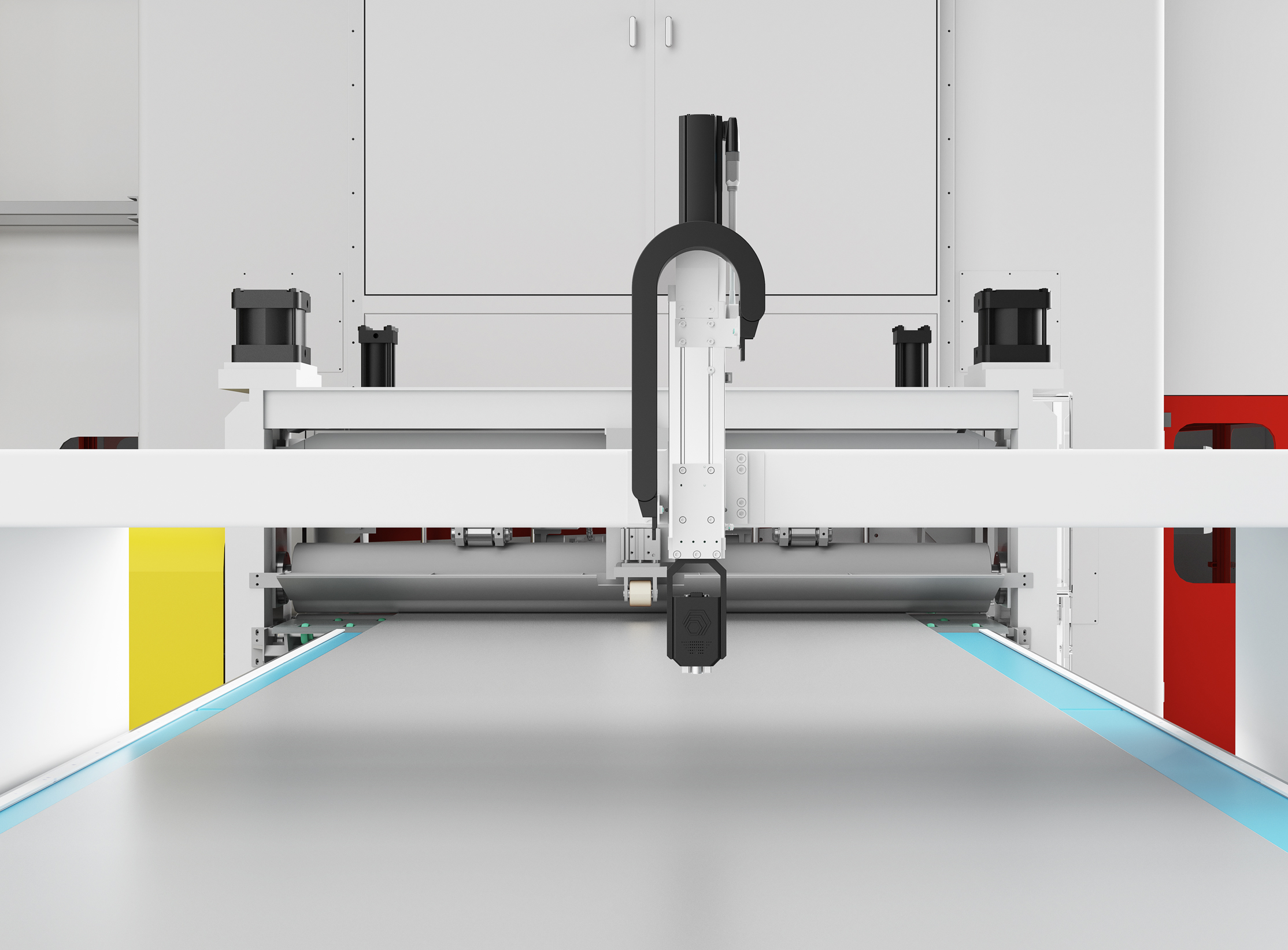

- 3

Sensor head

Modular design to add / eliminate sensor heads.

Optimized configuration adapted to your production requirements.

- 4

Multi-variable sensors

Our sensors can measure multiple electromagnetic signals simultaneously, allowing us to identify errors in your process.

- 5

BAT Software

Deep learning techniques to identify process deviations.

Advanced traceability systems for predictive maintenance purposes.

- 6

Calibration

Auto-zero cycle to calibrate the system.