Improve your processes. Avoid surprises and extra expenses.

BAT S

The flexible and modular machine series for non-destructive inspection of shafts

With the BAT series, you can carry out a complete inspection of the mechanical properties of your shafts non-destructively.

The different models of the series allow you to choose between statistical process control or 100% production control.

THE BAT S SERIES OFFERS THE FOLLOWING ADVANTAGES

Reduce the cost of inspection

Inspect heat treatment and grinding processes without destroying a single part.

By eliminating scrap and labour costs, our customers report savings of up to €250,000/year.

Increase productivity

Avoid destructive testing that takes hours and reduce inspection time to minutes or seconds.

Do not stop production while you inspect and increase your productivity by up to 6%.

Minimise incidents and non-quality costs

With the BAT S series, you choose to check 100% of the parts or perform a statistical process control.

Reduce the interval between inspections and avoid accidents that can cost millions of Euros.

Operate a user-friendly machine

You will get clear instructions and an interface specifically designed for plant personnel.

This makes operation, maintenance and result interpretation extremely intuitive.

Implement new part types

The BAT S series offers you an automatic model changeover for a wide range of products.

Learning new models is simple and, in many cases, you can do it yourself.

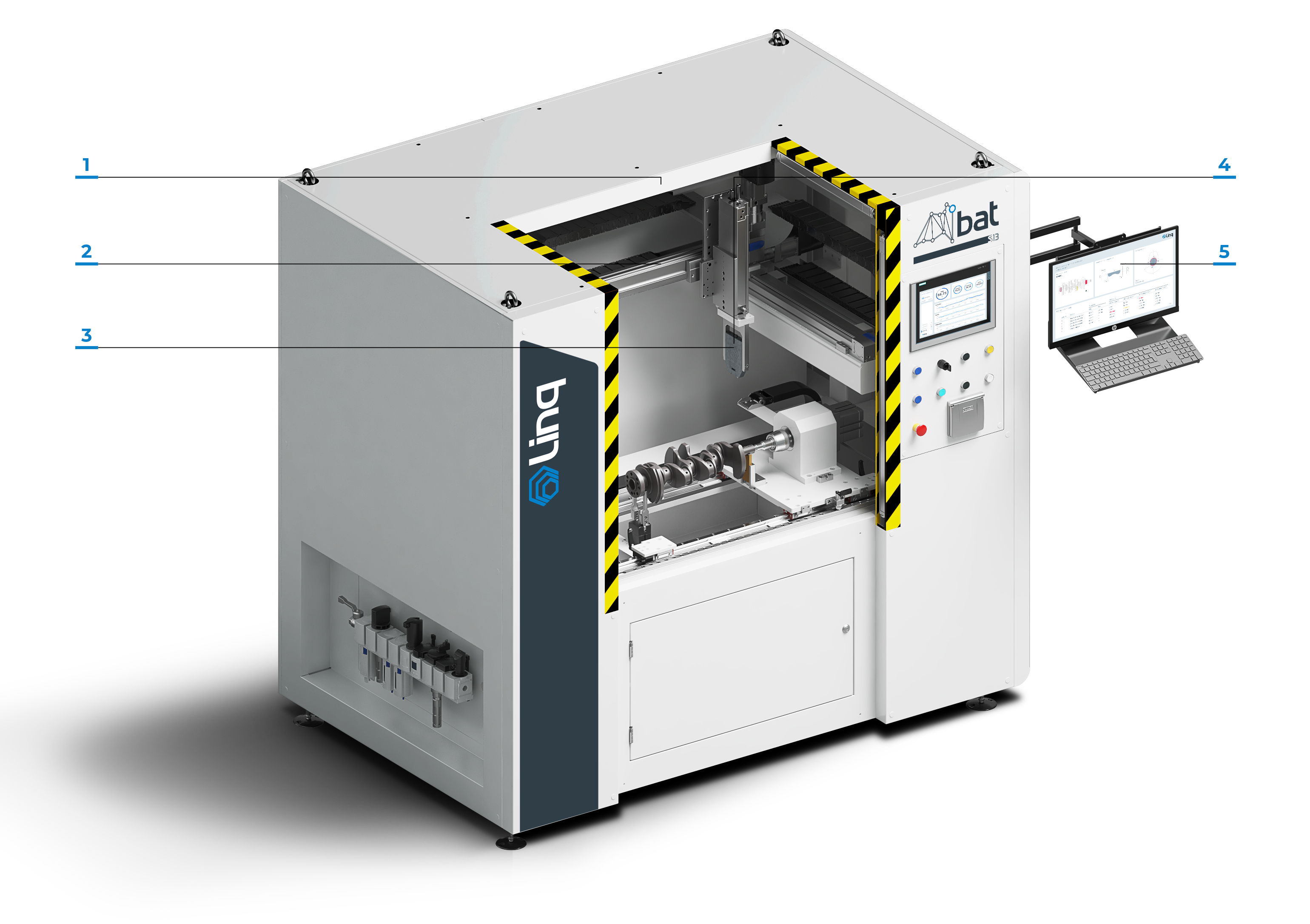

- 1

Load/unload options

Gantry, conveyor or manual loading.

- 2

Degrees of inspection automation

Fully automatic or semi-automatic inspection with operator intervention.

- 3

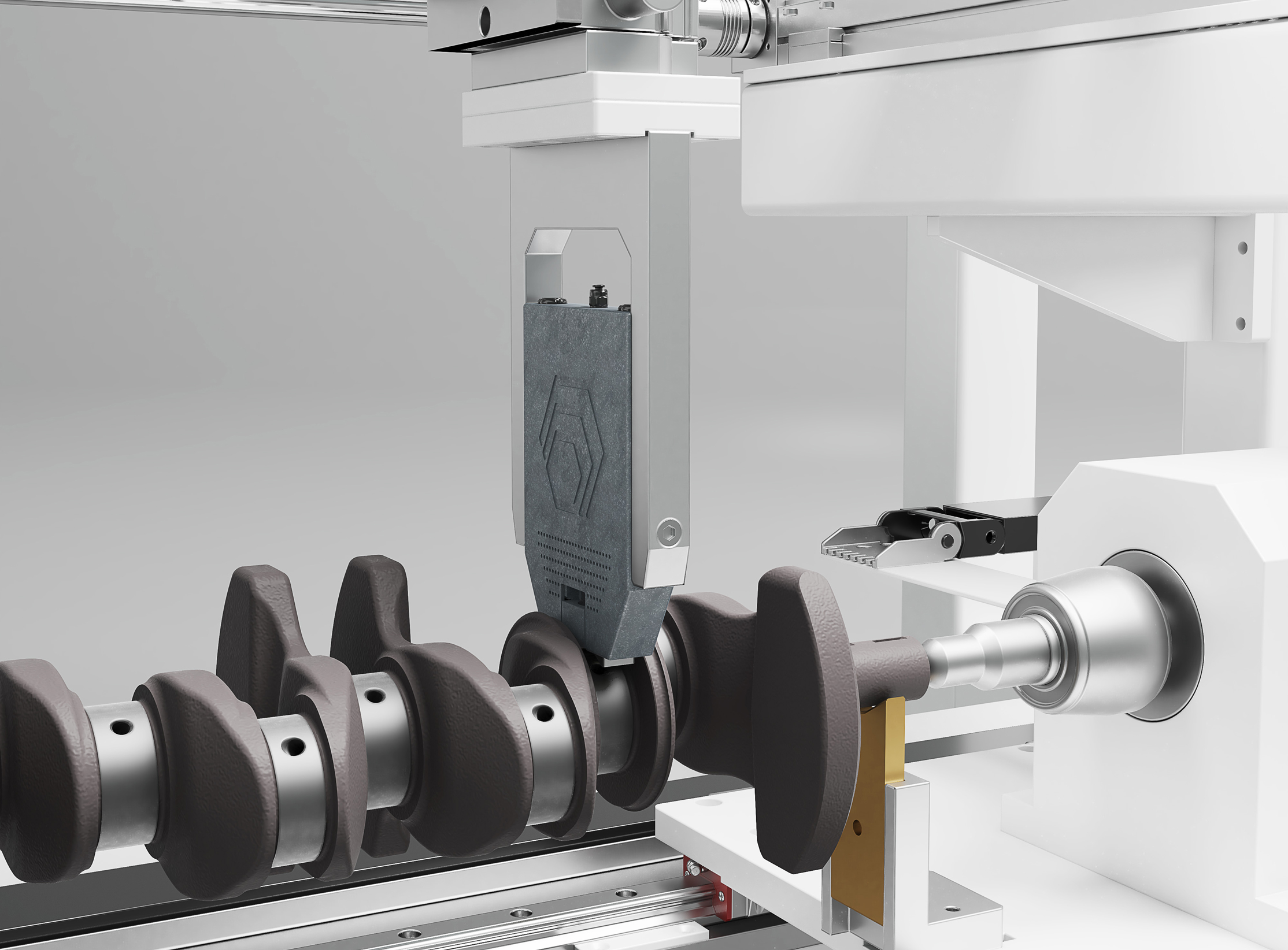

Sensor head

Modular design for 1 or 2 sensor heads according to your production requirements.

- 4

Multi-variable sensors

Simultaneous measurement of multiple electromagnetic variables, obtaining greater accuracy.

- 5

BAT Software

Software specifically developed for easy machine operation and intuitive interpretation of results.