Improve your processes. Avoid surprises and extra expenses.

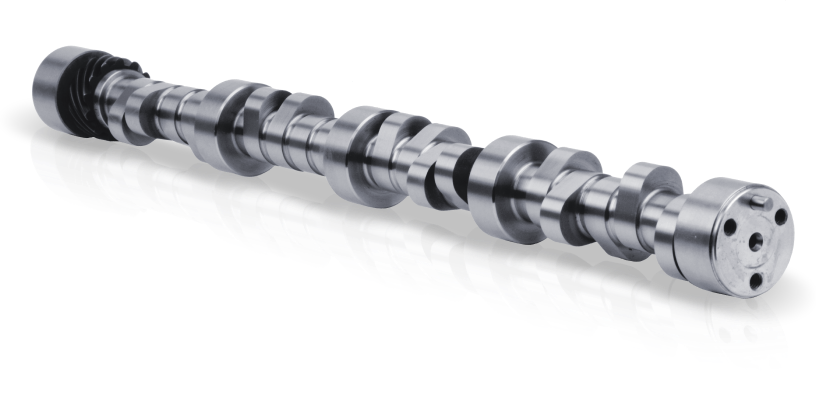

SHAFTS

Our NDT technology is suited to verify mechanical properties of ferrous metal shafts at different stages of their manufacturing process. The quality inspection can be performed manually or automatically respecting the line cycle time.

Inspected features

- Hardness

- Heat treatment case depth and pattern

- Grinding burns

- & more.

Components

- Crankshaft

- Camshaft

- Rotor shaft

- Input shaft

- & more.

OUR SYSTEM

Our sensor heads are designed to inspect journals of different widths and diameters. We can arrange multiple transducers in the same head to verify properties at different part locations simultaneously.

Inspection capabilities

We offer different inspection capabilities depending on the process stage of each part.

MECHANICHAL PROPERTIES

- Hardness (OK/NOK)

HEAT TREATMENT PROPERTIES

- Band width

- Hardness

- Hardened case depth

- Holes presence

- Overlap area

GRINDING BURNS

- Grind burns detection on journals and lobes

MECHANICAL PROPERTIES

- Heat treated / Not head treated